Frequently Asked Questions Page

Table of Contents:

(Click on any question!)

How do I care for my Woodturnings?

Simply dust them with a dry cloth or a feather duster as necessary.

It is important that they are NEVER washed with soap and water; wood will warp and/or crack by doing so.

What type of finish is used on Woodturning?

Most of the turnings have a clear lacquer finish. On some of the smaller items a Friction Polish is used or the piece is buffed with a Carnauba Wax.

Where is a good place to see Woodturnings?

First check Curt's Art Show

Schedule on the Home Page. The Old Market Artists Gallery (OMA) in Omaha has a wonderful display of Curt's woodturnings for you to view or go to there web site www.oldmarketartists.com You may also look on the internet under "Woodturning" for additional locations. The American Association of Woodturners www.woodturner.org has a great gallery page.

Who should I contact to get involved with Woodturning?

The American Association of Woodturners has over 19,000 members. Look on the internet to find a local chapter near you. www.woodturner.org. Two great places to get involved in this area is the "Omaha Woodturners Club" in Omaha, Nebraska and the "Great plains Wood Turners Club" in Lincoln, Nebraska .

Can I use my woodturnings to serve food?

Yes --- Your wood turning is an art form and can also be used to serve the most elegant green salad for your family and guests to enjoy! It is recommended that as soon as the meal is finished, you wipe the bowl clean with a warm, sudsy cloth then immediately dry it with a fresh, soft towel. It is also great for serving chips, bread, or other ‘dry’ types of foods.

Do not refrigerate your wood turned bowl. Not recommended for potato or other types of salads that remain in the bowl many hours.

NEVER soak or machine-wash your woodturning – that treatment will make the wood warp, or worse yet, crack.

What is a Hollow Form Turning?

Hollow Form woodturnings are usually in the form of a vase or vessel with the opening smaller than the vessel size or diameter. The inside shape conforms with the outside shape and most often the wall thickness ranges from 1/8" to 3/8". Once the wall thickness is established the artist strives to maintain a consistent thickness throughout the entire piece.

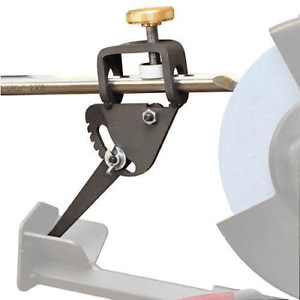

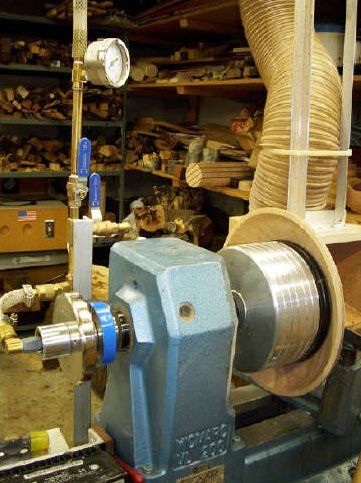

Here are pictures of my hollowing system. Once the outside form is turned between centers I then attach the piece to a large chuck on the lathe. While the piece is turning I open up the inside with the sharp cutting tool on the end of a bar that slides in a cradle which is attached to the lathe bed.

What is a Bud Vase?

A Bud Vase is a vase with a hole down the center for the stems of flowers to fit in. Be sure NOT to put water in the wood vase. "Water on Wood -- No Good!" Artificial or dried flowers work well.

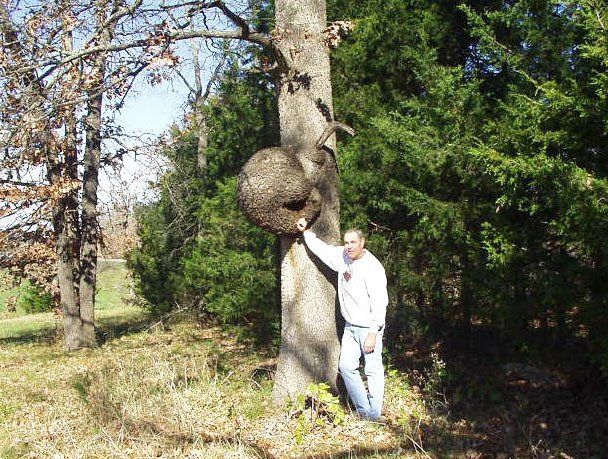

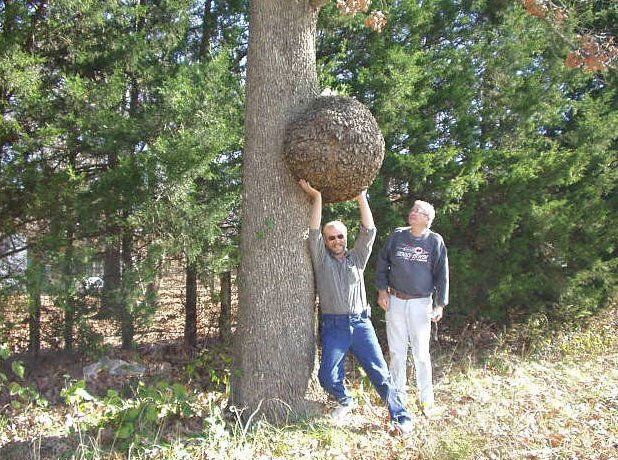

What is a Tree Burl?

They are basically benign tree tumors. They occur when a twig bud fails to grow normally,

differentiating into the tissues needed for forming a limb,

and instead just multiplies and multiplies and multiplies its bud cells.

That's how you get the round growth with an irregular grain structure.

Many burls will sprout when placed into water, forming normal-looking shoots.

Apparently the water saturation somehow helps them "remember" that they are, after all, limb buds.

Richard Barrans Jr., Ph.D.

Example: Oak Burl by Pomme de Terre Lake in Missouri. Close to the home

of Woodturner Dale Robbins. Curt on left, Dale Robbins & Gary Scott on right

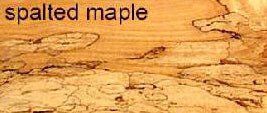

What is Spalting?

Spalting is a by-product of the rotting process that is carried out by a vast array of stain, mold and decay fungi, that are found naturally on the forest floor. When the temperature and humidity are right, spalting can cause many different and beautiful patterns in rotting wood. The unusual coloration may be due to chemically induced reactions between the wood, fungi and insect deposits, often resulting in black, pink, grey and multicolored streaked wood.

Once the wood has been cut and stabilized, the fungi can no longer grow, and the spalting process will stop.

Where do I get my wood?

Most of the wood I harvest myself in the local area around Omaha or with other members in our woodturning club. Some of the wood burls I buy from Oregon and

California. The Osage and Cedar are from

Missouri.

How do I control Wood Dust?

Dust Collection System in the wood shop is essential.... A necessary requirement.... A health issue....

My shop is equipped with a Grizzly G0548 - 2 Horsepower - 1,700 CFM Dust Collector with a Canister type filter that provides filtering of the air to 1 micron. I added a Oneida Dust Deputy with 6" ports on both in and out. The 6" to triple 4" Y

adapter at the Dust Collector is removed and 6" pipe is used for the main run with 4" drops to the all the equipment. For the drop down to the wood lathe I stayed with 6" flex pipe to a catch box. The box pivots back & forward and left to right to help keep the maximum dust collection in the area of interest. (The 1/4" bolts in the angle aluminum is where the pivot points are.) The 6" gate is homemade and works just as nice as the 4" gates I bought!

My Dust Collector at the Lathe

Grizzly G0548 Dust Collector

Oneida Super Dust Deputy

How do I Sharpen Woodturning Tools?

Working with SHARP tools makes woodturning very enjoyable and rewarding because of the finished product. A sharp cutting edge on the gouge, scraper or skew helps keep the wood fibers from getting torn. With the wood fibers having a nice clean cut from the sharp cutting edge of the tool the sanding requirements are reduced significantly. Most of my tool sharpening is done on the Grizzly G1015 knife belt sharpener. I added a 180 grit CBN (cubic boron nitride) wheel and use it most of the time. The 120 grit sanding belt is also handy for sharpening many tools.. The grinding fixture is a One Way Wolverine. They do a fantastic job of keeping the same bevel and cutting edge on the tool every time I sharpen, which is often.

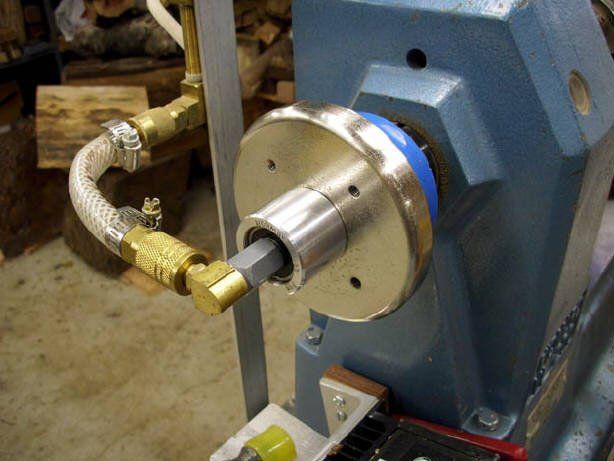

What is a Vacuum Chuck Holding System?

The basic principle of vacuum chucking involves the science of the atmosphere around us. Normal atmospheric pressure, at sea level, is just under 15 pounds per square inch. That means if we create a vacuum, such as a vacuum chuck, the barrier between the atmosphere and the vacuum, in this case our woodturning, has a pressure exerted upon it by the atmosphere.

Vacuum is measured in inches of mercury or Hg. A perfect vacuum is 30 inches of mercury (30 Hg) and cannot be obtained on the surface of the earth. Most of the small pumps we use for our type of work are able to provide 22 to 28 Hg, and this level of vacuum is more than sufficient for our purposes. In round numbers, the pressure exerted by the atmosphere is about one-half pound of force per square inch for every inch of mercury. This sounds confusing but your system will have a gauge that reads from 0 to 30 Hg. Divide the number on the gauge in half to find the pounds per square inch of force exerted on the turning. As an example; you have built a vacuum chuck that is 6 inches in diameter. You attach it to the lathe and apply vacuum to hold a woodturning. The 6 inch diameter chuck has just over 28 sq. ins. of surface (pi x r²). If you run the vacuum to 20 Hg, the external pressure on the piece is about 10 PSI times the 28 Sq. Ins. of the vacuum chuck and the force exerted against the woodturning is a total of 280 pounds. At 28 Hg the pressure increases to 392 pounds of force against the woodturning. ( pi x r² x ½hg = pounds of force)

VACUUM CHUCK HOLDING POUNDS

In Round Numbers

2 INCH CHUCK --------31 lbs. @ 20 hg 45 lbs. @ 28 hg

3 INCH CHUCK -------- 70 lbs. @ 20 hg 100 lbs. @ 28 hg

4 INCH CHUCK ------- 125 lbs. @ 20 hg 170 lbs. @ 28 hg

5 INCH CHUCK ------- 190 lbs. @ 20 hg 275 lbs. @ 28 hg

6 INCH CHUCK ------- 280 lbs. @ 20 hg 395 lbs. @ 28 hg

7 INCH CHUCK ------- 380 lbs. @ 20 hg 540 lbs. @ 28 hg

8 INCH CHUCK ------- 500 lbs. @ 20 hg 700 lbs. @ 28 hg

(Chuck size radius = r) pi X r² X ½hg = pounds of force on the woodturning

The pressure exerted by the atmosphere is about 1/2 pound of force

per square inch for every inch of mercury

Area in Square Inches of a Vacuum Chuck size =

pi r²

(3.14 X Radius Squared)

Inches of Mercury on the system gauge =

hg

Curt Norman 1/15/06

The vacuum seal on the vac chuck is Closed Cell Foam --- Craft Foam from Hobby Lobby

My Vacuum System on the Lathe with a OneWay chuck and home made chucks and vacuum adapter made by JTTurningtools.

Will I do Commissioned Work? ---YES--- Call Curt at 402-553-7222